PVC

SPAY N' LOCK

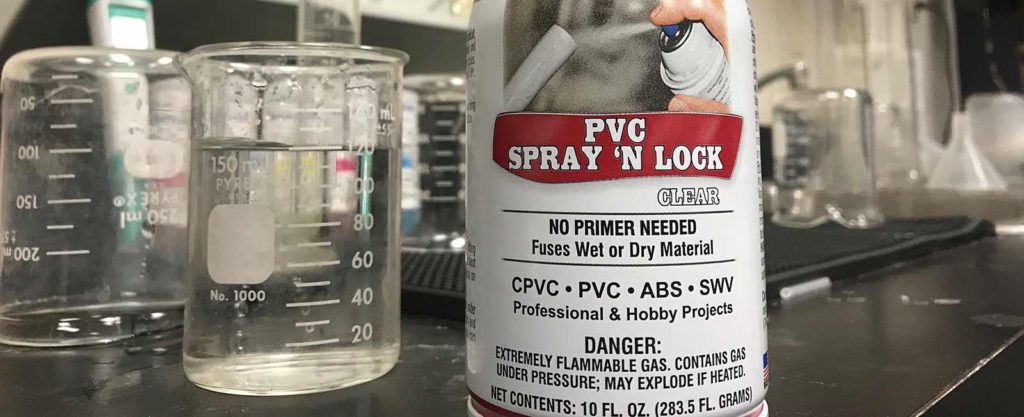

PVC SPRAY ’N LOCK™ does the impossible. It replaces the traditional multiple-product, multiple-step process of

cleaning, priming and cementing/gluing pipes with an easy-to-use, single application, chemical fusion spray.

Simply spray the product on the pipe and coupling … and they lock in place.

Bonding PVC, CPVC, ABS and DWV pipes and fittings can be challenging. Multiple products and multiple applications are often required. The process can be messy, wasteful, difficult, time-consuming and expensive. PVC Spray ’N Lock changes all that. It makes the job easy, and affordable. No longer do you need daubers, primers and cement. No longer do you have to worry about product spilling or drying out in cans or having to wait hours while it cures. With PVC Spray ’N Lock you simply spray the product on both pipe and fitting, wait a minute or two (depending on the type of pipe and temperature), and that’s it. No worries, no mess, no hassle, no waste … just a solid, permanent bond.

Features and Benefits

PVC Spray ’N Lock is perfect for HVACR, condensate drain lines, electrical conduits, ventilation pipes, irrigation, swimming pools,

lawn and garden, home and hobby projects and more!

- No Daubers or Primers Required

- Will Not Spill, Harden or Freeze in Can

- Quickly Fuses PVC CPVC, ABS and DWV pipes and fittings.

- Quickest Cure Time of any PVC bonding agent

- Pressure Tested to 215 psi

- Heat Tested to 140°F

- Passes ASTM D3452-06(2017) Water Potability

- Available in Purple and Clear

- Bonds wet or dry pipes in seconds

- Each can bonds approximately 100 joints of 3/4″ PVC pipe.

How It Works

PVC Spray ’N Lock is a solvent. It works by softening/separating the PVC molecules it is sprayed onto. As it evaporates the molecules harden/regroup. This means both pipe and fitting must be saturated with the product (with no gaps in coverage) in order to work properly. When done correctly, the Pipe and Fitting will become one piece of PVC, vice two. NOTE: PVC Spray ’N Lock was designed to bond similar type PVC material. For best results, use the same type PVC material (PVC, CPVC, ABS or DWV) when bonding. Results may vary if dissimilar types are used.

- PVC to PVC

- CPVC to CPVC

- ABS to ABS

- DWV to DWV

NOTE: Once PVC Spray ’N Lock is applied, pipe and fitting must be joined while the product is still saturated. Remember, bonding occurs during evaporation. DO NOT wait to join the pieces.

It is best to give the pipe a 1/4 turn (twist) upon insertion into fitting . This will help spread the product evenly.

Hold pipe for 10 seconds. Release. Unlike cement there is no push back.

Product will evaporate fully, giving you a strong permanent bond in 60 seconds (longer in colder temperatures – see Temperature Cure Times page ).

No further cure-time is required.

Insight

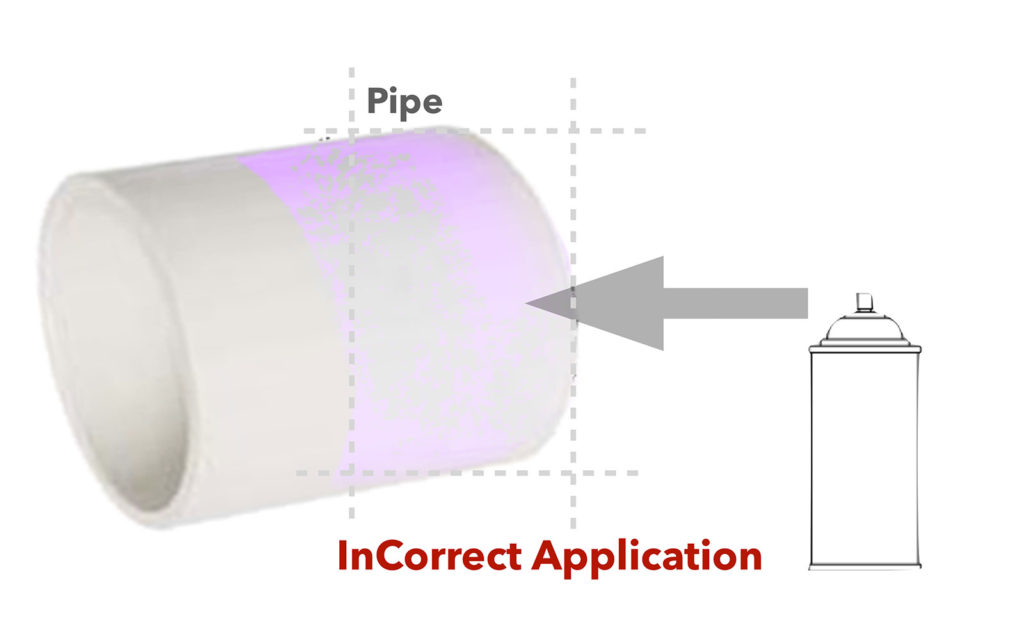

- Spray ’N Lock MUST BE applied evenly and thoroughly around the area to be bonded. Both pipe and fitting must be saturated with product.

Gaps in coverage, missed or thinly covered areas will create a weak bond.

Remember, the product must be completely covering the PVC material (on both pieces) to break it down. Apply liberally and thoroughly, covering both pipe and fitting completely.

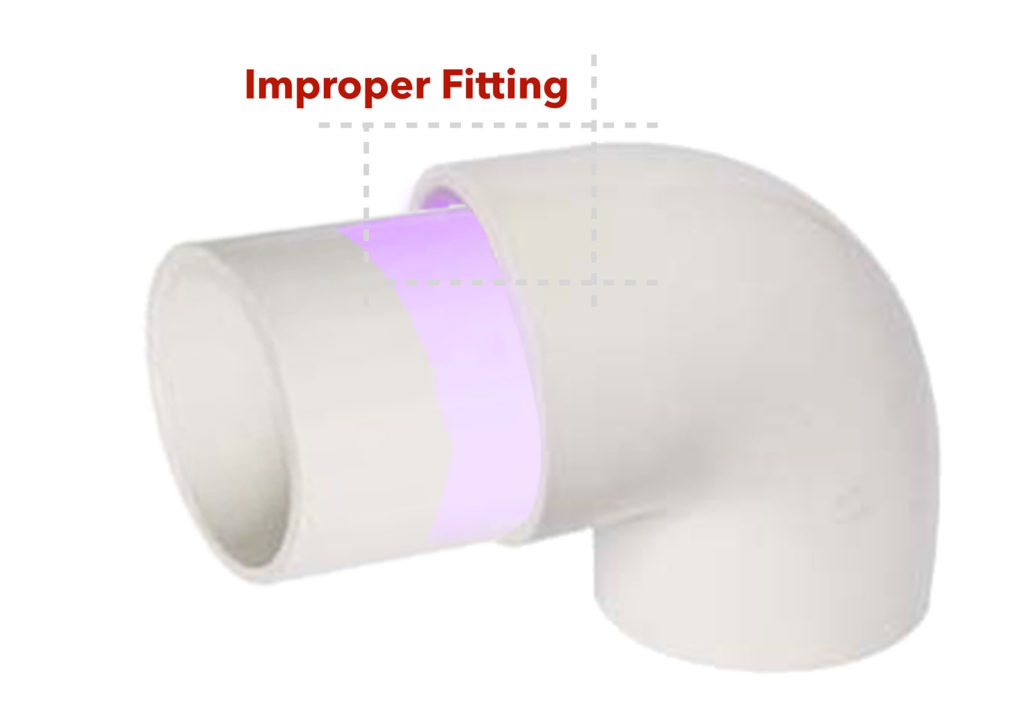

ALSO: Both pipe and fitting must fit together snugly (touching at all times). Improper, loose or misaligned connections will not provide the needed surface area for the product to work properly.

Directions

- Cut pipe square

- Remove dirt and burs

- Dry fit pipe and fitting

- Mark pipe for alignment

- Spray pipe and fitting

- Insert pipe into fitting

- Turn pipe 1/4 turn

- Hold pipe for 10 seconds

- Follow the directions above for the remainder of the joints.

NOTE: Product dries rapidly. Make sure PVC Pipe and fitting are wet with product on all sides before connecting. For best results, use on pipe 2” and under.

Temperature Cure Times

While PVC Spray ’N Lock will not freeze in the can, its cure time is retarded in colder temperatures. The below reference chart shows its tested cure times under cold conditions. We have also included the cure time for the leading PVC Cements under the same situation.

PVC pipe size: 1/2″ to 1-1/4″

- Temp: 60°F-100°F | PVC Spray ‘N Lock Cure Time: 60 Seconds | Leading PVC Cement: 1 hour

- Temp: 40°F-60°F | PVC Spray ‘N Lock Cure Time: 60 Seconds | Leading PVC Cement: 2 hours

- Temp: 20°F-40°F | PVC Spray ‘N Lock Cure Time: 4 minutes | Leading PVC Cement: 6 hours

- Temp: 20°F-20°F | PVC Spray ‘N Lock Cure Time: 10 minutes | Leading PVC Cement: 8 hours

PVC pipe size: 1-1/2″ to 2″

- Temp: 60°F-100°F | PVC Spray ‘N Lock Cure Time: 60 Seconds | Leading PVC Cement: 2 hours

- Temp: 40°F-60°F | PVC Spray ‘N Lock Cure Time: 60 Seconds | Leading PVC Cement: 4 hours

- Temp: 20°F-40°F | PVC Spray ‘N Lock Cure Time: 4 minutes | Leading PVC Cement: 12 hours

- Temp: 20°F-20°F | PVC Spray ‘N Lock Cure Time: 10 minutes | Leading PVC Cement: 16 hours

Water Potabilty and Pressure Test

St. Louis Testing Laboratories Incorporated, an independent chemical, metallurgical, mechanical, nondestructive, environmental testing, analysis and field service office, tested PVC Spray ’N Lock to determine its impact on the potability of pipe pater. A bonded pipe section was tested with potable water until the joint failed.

FINDINGS:

- PVC Spray ’N Lock does not negatively impact the potability of water purged through the system system within 1 minute of completed curing. ASTM D3452-06(2017)

- PVC Spray ’N Lock held tight up to 215 psi. Calibrated Pressure Gauge ID: MECH127

Jacob W. Long, Manager, Chemical Testing

March 20, 2019 Lab No. 19C-0268

Heat & Pressure Test

We put PVC Spray ’N Lock to the test in our laboratory recently. Here is what we did and what we discovered:

FINDINGS:

- We started by locking several pieces of 2” PVC Pipe together with PVC Spray ’N Lock.

- We then placed the locked pipe in an oven and set the heat to 140°F … and let it ‘cook’ for more than 100 hours.

- We then attached a nitrogen cylinder and weight to the pipe … and submerged the pipe into a 50 gallon barrel of water.

- We then applied pressure to the pipe, looking for any leaks. The bond held tight.

- We then added pressure, and more pressure and then more.

- We then maxed our pressure gauge at 150 psi.

- After 100 hours at 140°F, the bond held tight!